About

私たちについて

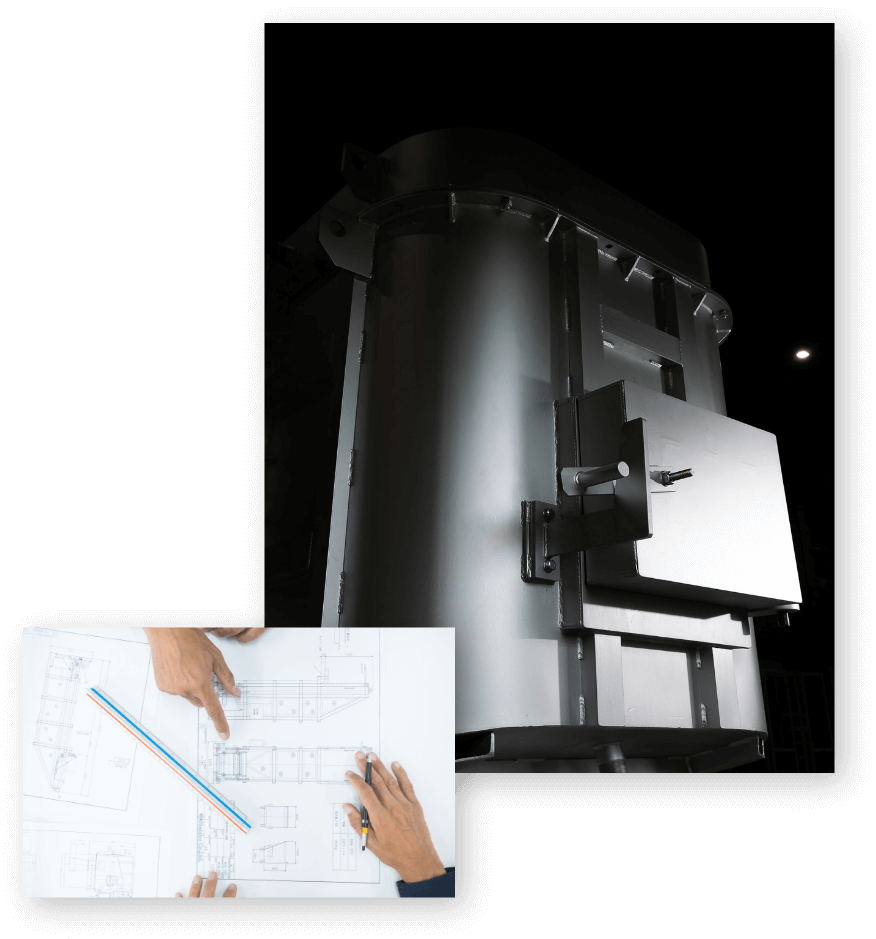

小型アルミ溶解炉の

リーディングカンパニー

メイチューは、設立以来一貫して、アルミ溶解炉を中心とした鋳造用設備及びその資材の製造販売並びに鋳造用諸資材の販売を行っております。

また、炉だけでなく、炉周りの設備や搬送用の機械などの自動化を進め、より効率的に、より安全に業務を行える環境のご提案で鋳造メーカーの皆様の更なる低コスト化に貢献いたします。

Solution

ソリューション提案

炉周りの自動化がモノづくりを加速させる

メイチューは、アルミ溶解炉において、「最適な溶解」を提供する炉メーカーです。炉だけでなくその周りの付帯設備の充実・自動化により、炉メーカーの域を超え、溶解の未来を変えていきたいと考えています。

SDGsへの取り組み

カーボンニュートラル達成のため、炉の構造を新たな視点から見直すこと、電化やエネルギー転換などの観点から研究を進め、2050年度までに新炉の開発を目指した、当社の具体的な取り組みをご紹介いたします。

Recruit

News

新着情報

- 2023.08.25 お知らせ

- 英国通信社「The Worldfolio」にインタビュー記事が掲載されました